Making pipes and their accessories

Task

Create two pipes, two front caps, two rear caps, two thermal

shields, and four slide covers.

Material needed

- 8-terminal and 6-terminal wire nuts

- 30cm of 4mm^2 insulated hard copper wire

- Smoke pipe

- Four smoke pipe caps

- Thin tin or durable plastic for the hoods

- Primer paint

- Top coat paint

- A piece of paper to wrap around the pipe for marking angles

- Two lenses

- Two 6mm cable bushings and seven 8mm cable bushings (they are numbered

according to diameter of cable that can be put into them).

- self-cutting screws 3.9x>=12mm

- self-cutting screws 3.9x>=6mm

- M3x15 bolts

- M3 nuts

- M4

- Sillica gel

- Sewing thread

- A small piece of old fabric

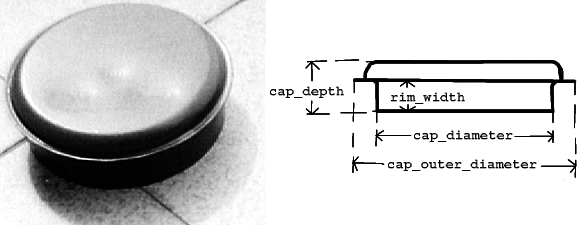

It is necessary the diameters of the lens and caps is as follows:

lens_diameter<=cap_diameter-15mm.

Action

|

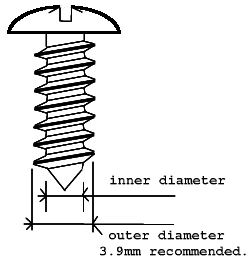

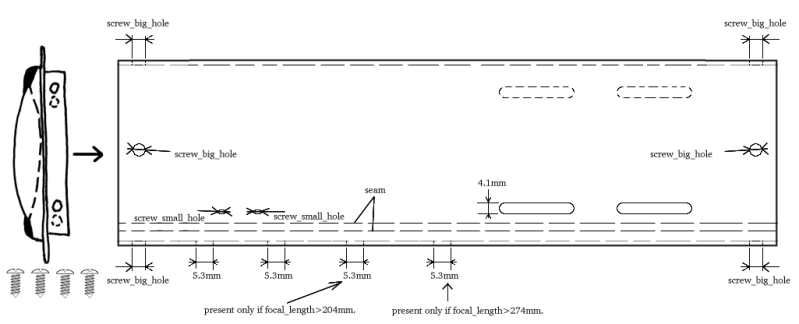

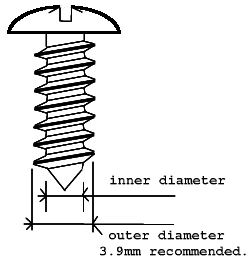

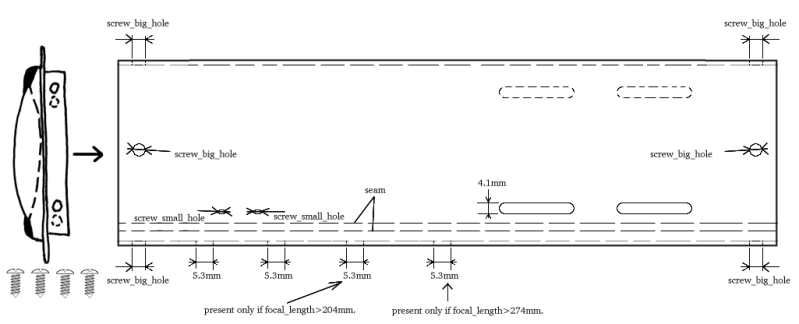

Take the self-cutting screws and measure screw_big_hole as the outer

diameter of the thread on the self-cutting screw+0.2mm and

screw_small_hole as the inner diameter of the thread on the

screw-0.2mm. |

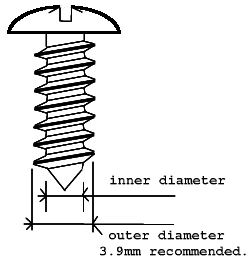

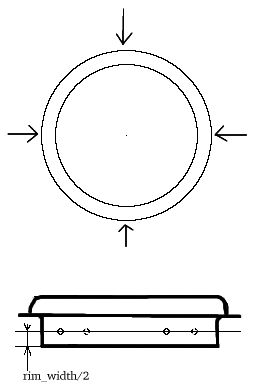

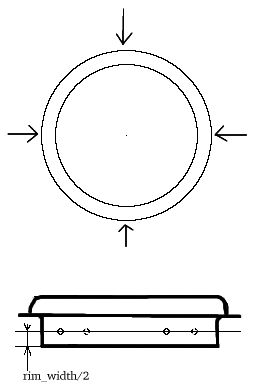

| Take the smoke pipe cap. Measure

cap_depth, rim_width, cap_diameter, cap_outer_diameter. Take the smoke

pipe and measure the average diameter smoke_pipe_nominal (it should

be the same as the number under which it was sold to you).

|

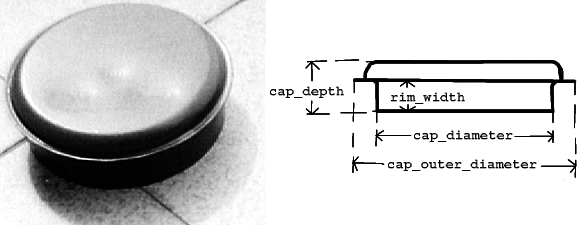

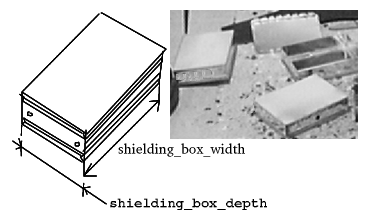

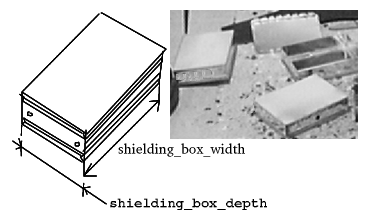

| Take the shielding box.

Measure shielding_box_depth and shielding_box_width.

|

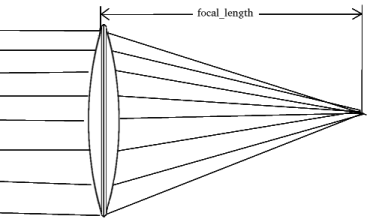

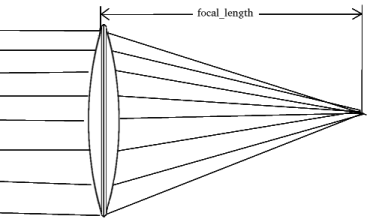

| Take the lens and focus an image of distant

object on horizon seen through an window onto a wall. Ask someone to

measure the focal_length on two opposite places on the rim of the lens.

Average them and this is the focal_length. Compute pipe_length as

focal_length-cap_depth+rim_width+shielding_box_depth+rim_width+14. |

| Cut two

pipe_length's from smoke pipe using a metal saw. |

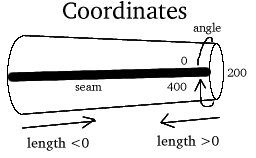

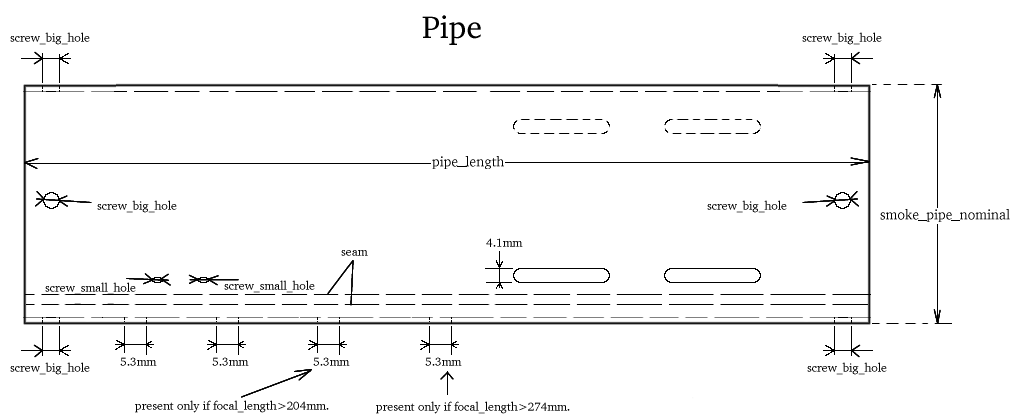

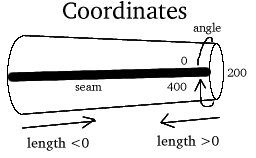

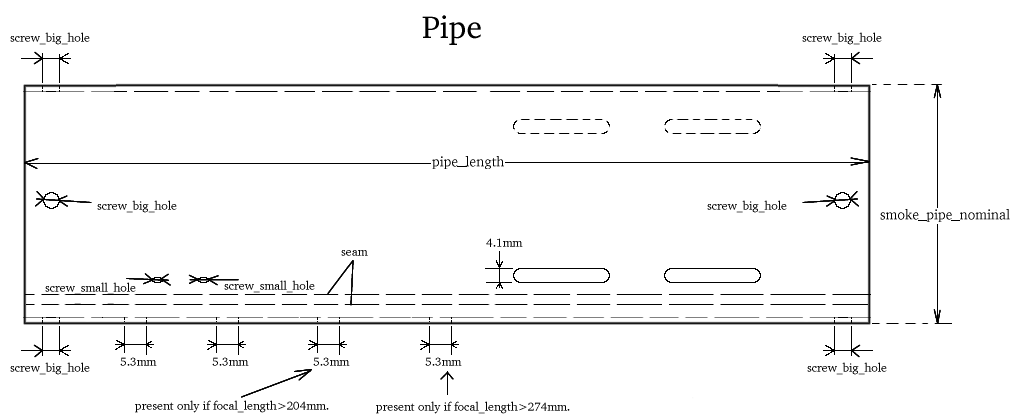

| In the next, we will describe coordinates on a cylinder - by angle and

length from one edge. Drill both cylinders (smoke pipes) in the same

manner. Measure length so that positive lengths are measured from the

narrower end of the tube and negative lengths are measured from the

opposite end. Measure angle so that zero is on the seam of the tube. First

comes angle in grads (from 0 to 400), then offset in

milimeters. |

|

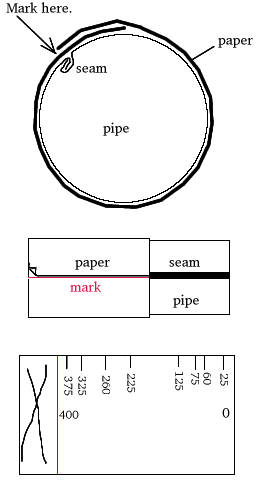

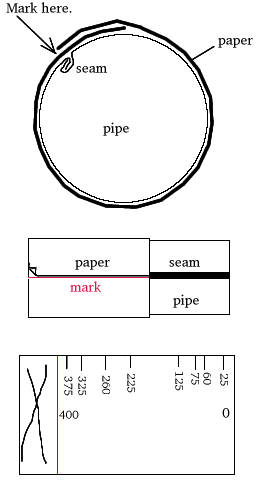

Use a sheet of paper wrapped around to measure the angle.

Wrap the paper around

and make a circumference mark where the edge is. Then put the paper on

desk and divide the circumference by 400 and make marks at 25, 60, 75,

125, 225, 260, 325, and 375 times this distance. Mark them 25grad, 60grad,

75grad, 125grad, 225grad, 260grad, 325grad, 375grad. Use calculator. Then

wrap the paper around again, the seam of the paper on the seam of the

tube, and copy the marks from the paper onto the tube as necessary. that

diameter of the tube is not constant, smoke pipes are slightly conical, so

recalibrate the marks for each set of holes.

|

Compute rim_offset as rim_width/2-3. Compute front_slide_offset as

focal_length-cap_depth+rim_width+2. Compute rear_slide_offset as

front_slide_offset+shielding_box_depth-16.

Drill these holes:

| Angle | Axial Offset | Hole

diameter | Purpose of the hole |

| 25grad | rim_offset | screw_big_hole | Holds

front cap |

| 125grad | rim_offset | screw_big_hole | Holds

front cap |

| 225grad | rim_offset | screw_big_hole | Holds

front cap |

| 325grad | rim_offset | screw_big_hole | Holds

front cap |

| 25grad | -rim_offset | screw_big_hole | Holds

rear cap |

| 125grad | -rim_offset | screw_big_hole | Holds

rear cap |

| 225grad | -rim_offset | screw_big_hole | Holds

rear cap |

| 325grad | -rim_offset | screw_big_hole | Holds

rear cap |

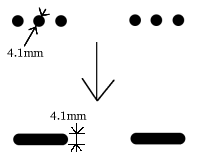

| 60grad | front_slide_offset-10mm | 4.1mm | Future

slide path |

| 260grad | front_slide_offset-10mm | 4.1mm | Future

slide path |

| 60grad, | front_slide_offset | 4.1mm | Future

slide path |

| 260grad | front_slide_offset | 4.1mm | Future

slide path |

| 60grad | front_slide_offset+10mm | 4.1mm | Future

slide path |

| 260grad | front_slide_offset+10mm | 4.1mm | Future

slide path |

| 60grad | rear_slide_offset-10mm | 4.1mm | Future

slide path |

| 260grad | rear_slide_offset-10mm | 4.1mm | Future

slide path |

| 60grad | rear_slide_offset | 4.1mm | Future

slide path |

| 260grad | rear_slide_offset | 4.1mm | Future

slide path |

| 60grad, | rear_slide_offset+10mm | 4.1mm | Future

slide path |

| 260grad | rear_slide_offset+10mm | 4.1mm | Future

slide path |

| 75grad | 40mm | screw_small_hole | Holds

hood |

| 375grad, | 40mm | screw_small_hole | Holds

hood |

| 75grad | 70mm | screw_small_hole | Holds

hood |

| 375grad | 70mm | screw_small_hole | Holds

hood |

| 25grad | rim_width+7mm | 5.3mm | Mounts pipe on

the holder's heel |

| 25grad | rim_width+77mm | 5.3mm | Mounts pipe on the holder's

heel |

If the focal length is longer than 204mm drill also this:

| Angle | Axial Offset | Hole

diameter | Purpose of the hole |

| 25grad | rim_width+147mm | 5.3mm | Mounts pipe on the holder's

heel |

If the focal length is longer than 274mm drill also this:

| Angle | Axial Offset | Hole

diameter | Purpose of the hole |

| 25grad | rim_width+217mm | 5.3mm | Mounts pipe on the holder's

heel |

|

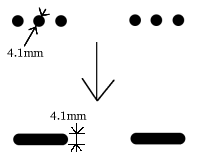

Connect holes

in each group of three holes marked for future sliding path together to

form a sliding path for the screws. Use a tiny file or fret-saw to

accomplish this. |

|

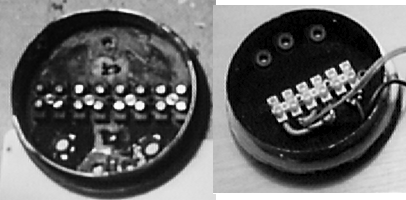

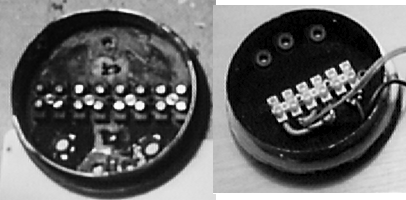

Remove any rust from the pipe (outside and inside) with emery paper. Wash

any traces of fat from the pipe using detergent, water and handbrush or

old toothbrush. Dry the pipe completely. Now the pipe should look as on

the picture. |

|

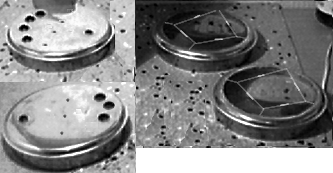

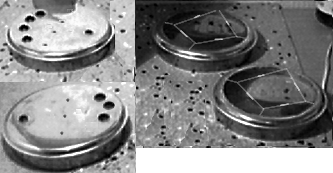

Now we will manufacture the four caps: two front ones, one rear

receiver and one rear transmitter cap. |

|

Take all four caps and for each cap, drill four screw_small_hole holes

rim_width/2 from the edge, symmetrically around both caps' rim (each cap

will get four holes). Use the sheet of paper to measure the diameter,

make the marks and transfer them to the cap. Be precise, otherwise you

will have problems screwing the caps into place. |

|

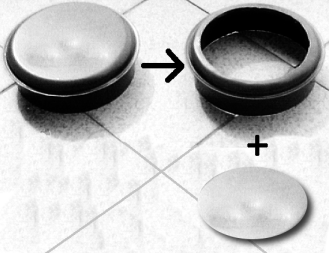

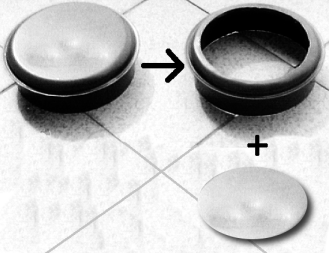

Take two caps. Make a mark in the center of the outer side using the

hard stylus and hammer. Place compasses into it and set compasses radius

to lens_diameter/2-1mm. Draw a circle. Make the circle more visible by

redrawing it using the marker pen. Put a block of wood into a vice and the

cap over it, the rim down. Use cold chisel and hammer to chisel out the

curve. Then the round piece will fall out. Collect it, it will be the so

called thermal shield. Use the hammer to repair the face of the cut on the

wooden block. |

|

Now we will make holes for the wire nuts and cable glands in the rear

caps. Take the rear receiver cap. Take a 8-terminal wire nut and place it

inside the cap, so that it points in a direction between two opposite

holes on the rim. Drill a 3.1mm hole between terminals 1 and 2, 3 and 4, 5

and 6, 7 and 8. Drill one 8mm hole on one side of the wire nut and four

10mm holes on the other side.

them. |

|

Take the rear transmitter cap. Take a 6-terminal wire nut and place it

inside the cap, so that it points in a direction between two opposite

holes on the rim. Drill a 3.1mm hole between terminals 1 and 2, 3 and 4, 5

and 6. Drill one 8mm hole on one side of the wire nut and three 10mm holes

on the other side.

|

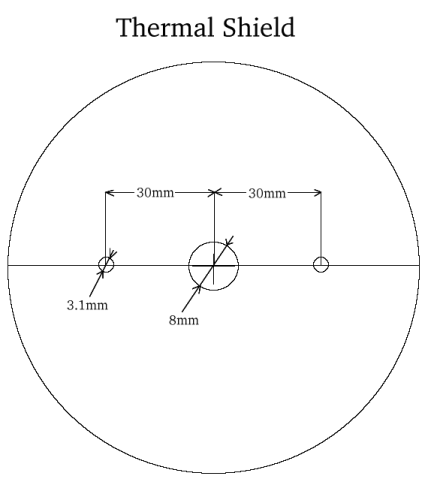

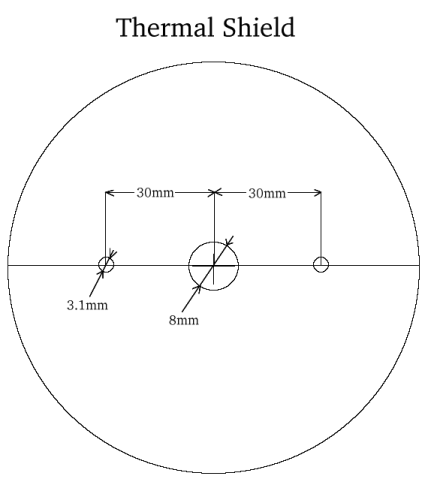

| Now we

will make two thermal shields. Mark a straight line across the thermal

shield, going throught the centre. Mark two holes, each 30mm from the

centre, on the line. Drill the centre out with a 8mm drill and the holes

each with 3.1mm drill. |

|

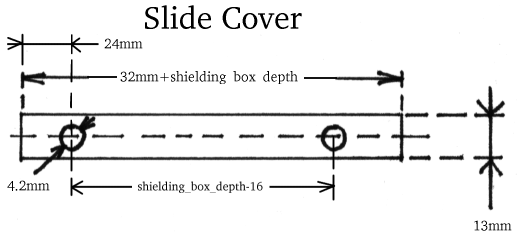

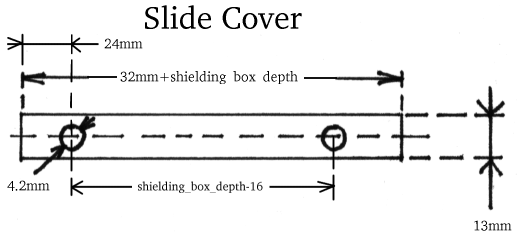

Make four slide covers from any scrap tin, 13mm wide and

32mm+shielding_box_depth long. Drill two screw_big_hole

diameter holes on each cover, shielding_box_depth-16 apart,

24mm from the end. |

|

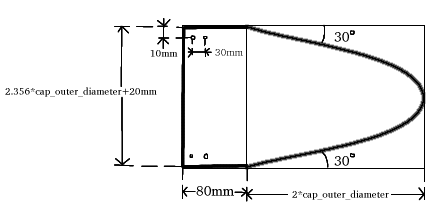

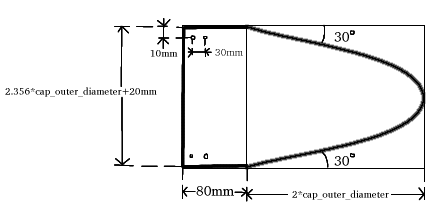

Cut two shapes from the hood tin (or plastic foil) as specified on the

drawing. Drill screw_big_hole through it as specified in the drawing.

|

Use emery paper to remove any

rust from the surface of pipes, caps, thermal shields, hoods, and slide

covers. Use detergent and water to wash out every trace of fat from the

surface of pipes, caps, thermal shields, hoods, and slide covers. Do it

really thoroughly, otherwise the paint will have reduced lifetime. Dry out

caps, pipes, thermal shields, hoods, and slide covers with the dry rag. The

pieces should be so clean they leave no smudges on the rag.

Clean the lenses thoroughly using

detergent, warm water, and dry them with a clean dry rag.

|

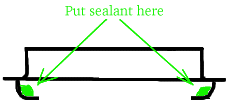

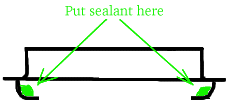

Place a fair amount of the sealant inside both front caps, into the

corner

where the lens will sit, but not on the edge on which the lens will sit.

|

|

Put the lens into the place from inside the cap and shape and finish the

sealant with your little finger so that it becomes smooth and flawless.

Take a great care not to smudge the lens. Do not place the sealant on the

outer side of the lens.

If you have smudged the lens and decreased clear aperture, wait

until the sealant partly solidifies and then remove it mechanically and

clean the remaining haze with a rag and acetone. Removing the hardened

selalant is not easy and must be done using a razor blade, without

scratching the lens. |

|

Put cable bushings into the holes in rear caps: 6mm bushings into 8mm

holes and 8mm bushing into 10mm holes. Seal them all against the cap from

both sides with the sillicone sealant. |

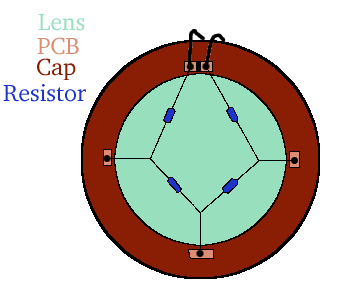

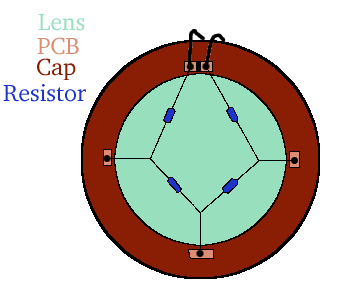

| Wait until the

sealant solidifies on all caps. Now we will furnish both front caps with

heating network. For each cap, cut four small pieces of PCB blank and cut

the copper on one side of one piece into two pieces insulated by a gap.

Solder these pieces regularly on the outer rim of the lens, on the tin.

Each piece goes near one hole for screw that is already there. Solder the

resistors there as specified in the drawing, connecting them to the rim

with pieces of bare wire. Check that there is no short circuit between the

network and the metallic cap itself. Wash both caps again with detergent,

warm water and dry them into the clean dry rag. Cut two pieces of

two-conductor 1.5mm^2 insulated cord, pipe_length+100mm long. Soler each

one on the terminals of the heating network. |

Now we will paint with water-soluble primer. Paint only those parts of

the specified list which are able to corrode, i. e. they are from raw steel or

iron and are not galvanized nor tin-plated. Paint caps, pipes (including

inner surface), hoods,

slide covers, and thermal shields with water-soluble primer. Wash out the

brush in a sink. Leave the caps, pipe , thermal shield, hoods and slide

covers to dry. Paint the same things with another layer of water-soluble

primer. Wash out the brush in a sink. Leave the caps, pipe, hoods, thermal

shields, slide covers to dry.

Now we will paint with water-soluble matte black top coat. Paint all

surfaces including those that do not corrode. Paint caps, pipes (including

inner surface), hoods, slide covers, and thermal shields. Wash out the

brush in a sink, leave the stuff to dry. Repeat once more to make another

layer of water-soluble matte black top coat. Leave the caps to dry. Prick

out the paint from all the holes on caps, pipes, hoods, slide covers, and

thermal shields using something sharp.

|

Screw the wire nuts

into their apropriate places using the M3x15 screws and M3

nuts. |

|

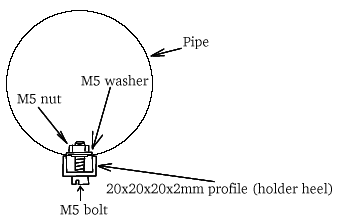

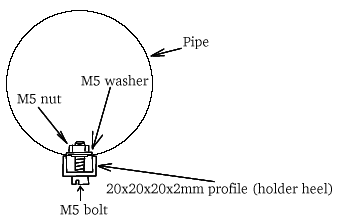

Attach the pipes to the heel of your holders using 4-8 M5 bolts, 4-8

M5 nuts and 4-8 M5 washers (depends on focal length). Mount is as in the

picture, tighten firmly. |

Screw the hoods in place using

eight galvanized M4 washers and eight self-cutting screws 3.9x>=6mm

|

Screw the front caps into both pipes using four self-cutting screws

3.9x>=12mm for each pipe. Seal the front caps against the pipe,

including the screws, with sillicone sealant. |

|

Divide the sillica gel into two equal parts and sew small bags from a

piece of old fabric. Put the sillica gel into them and sew them up. Put

them into oven (at minimum heat) for an hour unless you are sure the

sillica gel is completely dry.

Store the bags in a sealed plastic bag or container.

The caps, pipes, and slide covers are ready at the moment.